Introduction

Are you finding it challenging to keep up with the rapidly evolving automotive industry? Do you struggle with managing the complexities and competitiveness that define this dynamic sector? We understand your concerns, and that’s why we’re here to introduce you to a game-changing solution: Custom Automotive ERP (Enterprise Resource Planning) Software.

In 2023, the International Energy Agency reported a significant shift in consumer preferences, with nearly 2.3 million electric vehicles sold. This indicates a pressing need for automotive manufacturers to adapt and innovate. Imagine having a tool that not only streamlines your operations but also boosts efficiency, reduces costs, and enhances customer satisfaction. Custom ERP software offers just that, tailored to your specific needs and challenges.

To help you navigate these challenges and capitalize on opportunities, We provide Custom ERP Software designed specifically for the automotive industry. Our ERP solutions streamline operations, provide real-time data and analytics, and empower you to make informed decisions.

In this blog, we’ll delve into the challenges faced by the automotive industry, the benefits of Custom ERP Software, and why they are essential for automotive manufacturers looking to thrive in this competitive landscape.

Why Automotive Industry Need ERP System?

ERP systems are like the backbone of operations in the automotive industry. ERP systems streamline everything from manufacturing to supply chain management, inventory control, and customer relationship management, all in one integrated system.

Imagine having real-time visibility into every step of your production process. ERP systems make that possible, helping you manage your resources efficiently and plan your production effectively. ERP system also simplifies the complexities of supply chain management by optimizing inventory levels and tracking materials from suppliers to the assembly line.

Moreover, ERP systems enhance customer relationship management by providing valuable insights into customer preferences and buying behavior. This allows you to tailor your products and services to meet customer needs more effectively.

Challenges in the Automotive Industry

- Sustainability: The automotive industry is under pressure to meet stringent emissions regulations and consumer demand for eco-friendly vehicles. Automotive manufacturers need to innovate and invest in sustainable solutions to reduce their carbon footprint and meet regulatory requirements. According to the European Commission, The European Union plans to implement a 55% reduction in CO2 emissions from cars and vans by 2030 compared to 2021 levels.

- Technology Integration: Rapid advancements in technology, including autonomous driving and connected cars, require automotive manufacturer to integrate these technologies into their vehicles. This necessitates significant investment and expertise in cutting-edge technologies. A Deloitte survey found that 71% of global consumers are interested in connected car features such as remote diagnostics and in-vehicle Wi-Fi.

- Supply Chain Management: Managing a complex supply chain with multiple suppliers and components is a challenge for automotive manufacturers. Ensuring a steady supply of high-quality components while mitigating risks such as disruptions due to natural disasters or geopolitical factors is crucial. A 2023 study by Deloitte found that 79% of automotive executives consider supply chain disruptions a high or very high risk.

- Global Complexities: The automotive industry operates in a global market with varying regulations, market fluctuations, and currency exchange rates. Automotive manufacturers need to navigate these complexities to maintain profitability and sustain growth. The Society of Motor Manufacturers and Traders (SMMT) reported a 16% decline in UK car production in 2022 compared to 2021.

- Competition: The automotive industry is highly competitive, with traditional automakers facing competition from Tech giants like Apple, Google, and Baidu are actively investing in autonomous vehicle development, posing a threat to traditional automakers. To stay ahead, automotive manufacturers need to differentiate their products and provide exceptional customer experiences.

How ERP Systems Improve Vehicle Manufacturing

We understand the transformative power of automotive ERP systems in revolutionizing vehicle manufacturing. Our expertise lies in leveraging these systems to reshape the automotive industry in ten impactful ways:

- End-to-end Supply Chain Monitoring: Gain real-time visibility into your supply chain, from procurement to assembly line delivery. Our automotive ERP solutions enhance logistics operations, streamline manufacturing processes, and ensure timely component delivery.

- Production Planning & Execution: Plan resource allocation and production processes efficiently. Our ERP systems consolidate data to execute production according to plan, ensuring deadlines are met with high-quality products and minimal costs.

- Inventory Management: Simplify the management of inventories across departments. Our custom ERP software provides an accurate picture of inventory quantities, preventing shortages and reducing carrying costs.

- Quality Assurance: Maintain high-quality standards with integrated quality assurance processes. Our ERP systems help identify production defects and uphold quality expectations.

- Financial Management: Make production financially lean and cost-efficient. Our ERP software simplifies end-to-end financial processes, providing a comprehensive view of financial data across departments.

- Customer Relationship Management (CRM): Enhance customer satisfaction levels with our integrated CRM systems. Gain valuable insights for personalized marketing initiatives, brand differentiation, and managing customer relationships.

- Regulatory Compliance: Stay compliant with the latest regulations. Our ERP systems ensure manufacturing processes align with compliance goals and practices, avoiding penalties.

- Real-time Data Analytics: Make informed decisions with advanced data analytics capabilities. Our ERP systems provide real-time insights across the value chain, optimizing processes and improving performance.

- Warranty & Service Management: Enhance customer satisfaction and brand loyalty with efficient warranty and service management. Our ERP systems facilitate auto-updates and coordination for servicing schedules and repairs.

- Equipment & Asset Management: Maximize equipment and asset lifecycle with real-time updates. Our ERP systems aid in better planning, cost reduction, and resource maintenance, ultimately delivering higher-quality products.

Venturesathi is dedicated to helping automotive manufacturers stay competitive in today’s market. Our automotive ERP solutions are designed to meet the evolving demands of customers and regulatory bodies, ensuring efficient and streamlined manufacturing processes.

Read this Article to discover how custom software can integrate with your existing systems seamlessly.

Automotive Manufacturers Are Using ERP Systems and Why You Should Too!!

Let’s explore why modern automotive manufacturers are turning to ERP systems designed for the automotive industry.

- Increased Real-time Data Access: Our ERP systems streamline information flow, consolidating data from every department. This empowers decision-makers with up-to-date information on customers, resources, employees, and manufacturing status, all accessible in one solution.

- Secured Data: Our ERP systems ensure data security, especially when deployed on the cloud. Data is protected with automatically scheduled backups, preventing loss or failure. Cloud providers manage data security, updates, and storage.

- Enhanced Inter-organizational Communication: ERP breaks down communication barriers between teams and departments, allowing authorized personnel to access and manage data. Management gains a holistic view of the organization and departmental activities.

- Greater Compliance: Our ERP solutions meet the stringent quality standards of the automotive industry. They facilitate detailed labeling, Accepted Quality Level (AQL), and Rejected Quality Level (RQL) tracking, ensuring adherence to quality parameters.

- Inventory Optimization: Our ERP systems help manage inventory and warehouse operations efficiently, reducing surplus inventory and preventing stock-outs. Our ERP system facilitates report generation, inventory capture, and warehouse transfers.

- Automation of Tasks: Our ERP systems automate tasks such as generating reports, delivery notes, and invoices, saving time, and effort, and reducing errors.

- Lower Costs and Higher ROI: Cloud-hosted ERPs eliminate the need for multiple servers and IT professionals for installation and configuration. This lowers costs and improves ROI through optimized production, increased efficiency, and improved customer satisfaction.

- Quality and Customer Relations: Our ERP solutions enhance quality assurance processes and reports, ensuring that quality standards are met, and products are delivered on time, leading to improved customer satisfaction.

- Employee Efficiency: Our ERP systems automate operations, reduce data redundancy, and allow data access from handheld devices, improving employee satisfaction and efficiency.

- Optimization of Resources: Our ERP solutions drive lean manufacturing, helping businesses develop lean supply chains for optimum resource utilization, improved lead time, and reduced waste.

Read this article Our Toolbox for Manufacturing Success: Custom Software Development Services. This article will give you a deeper insight into how we develop custom software based on your specific needs and desires to enhance the overall efficiency of your business.

Takeaway

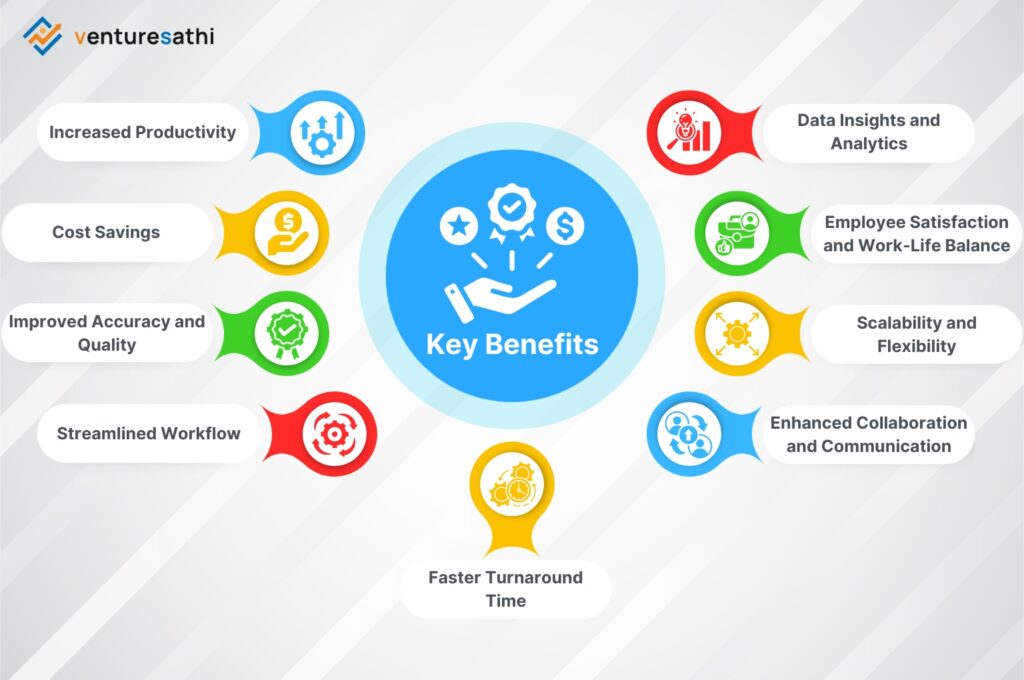

Custom ERP solutions are the driving force behind successful automotive manufacturing. These tools are your ticket to streamlined operations, boosted efficiency, and staying ahead of the curve in a competitive market.

Automotive manufacturers looking to stay competitive in today’s fast-paced automotive industry should strongly consider implementing custom ERP solutions. These solutions aren’t just about tackling today’s challenges; they’re about future-proofing your operations and setting yourself up for lasting success.

Ready to rev up your manufacturing processes? Get in touch with us today. Our team specializes in crafting custom ERP solutions that fit your needs like a glove. Let’s collaborate and take your automotive manufacturing to the next level together!

The valuable information that you have shared about the software related is really amazing to understand. Subscribed your blog.

Thanks for sharing insights into Custom Automotive ERP Software. It’s clear ERP solutions streamline operations, enhance efficiency, and ensure compliance, crucial for staying competitive in the automotive industry.”

Wow, this is exactly what I’ve been looking for!

I never considered custom ERP software before, but the breakdown of the benefits is super convincing. Real-time data, improved production planning, even better customer service – that sounds like a game-changer.

Especially interested in the end-to-end supply chain monitoring – streamlining that whole process would be a huge win for us.

Thanks Venturesathi for such an informative post!