How can your manufacturing business keep pace with the ever-changing market demands and technological advancements? The key lies in integrating custom manufacturing software with your existing systems. A 2020 report by Deloitte found that manufacturers who leverage digital technologies like integrated software can achieve a 20% increase in operational efficiency. These figures underscore the transformative potential of integration in the manufacturing industry.

In today’s fast-evolving manufacturing environment, maintaining efficiency and accuracy is more critical than ever. By integrating custom software solutions with your current systems, you can streamline processes, enhance data accuracy, and improve your bottom line. This blog will delve into the significance of integration and the numerous benefits it can offer to your manufacturing operations.

Streamline your manufacturing operations. Explore Venturesathi’s software solutions today.

Integrating Custom Manufacturing Software

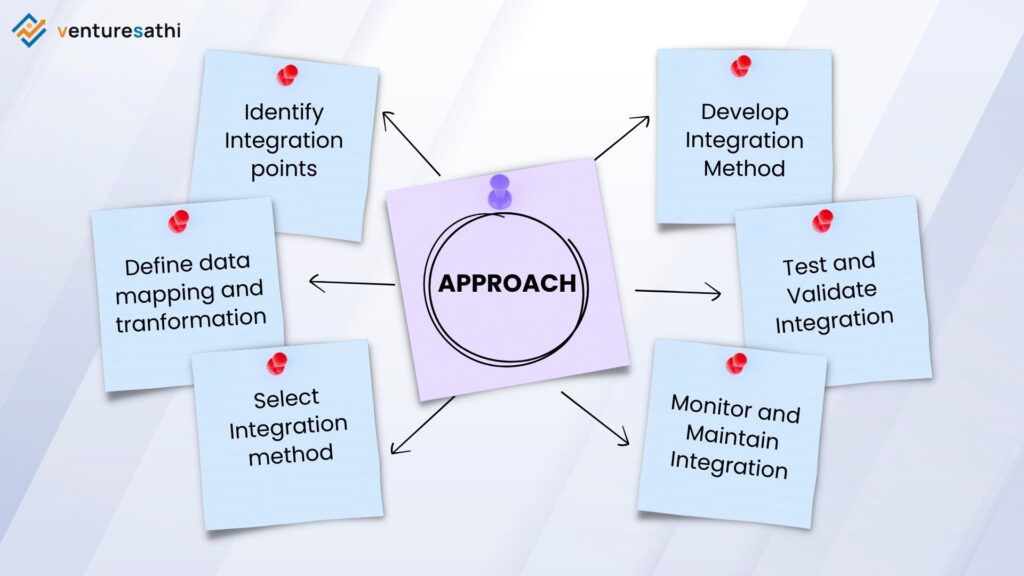

Integrating custom manufacturing software with existing systems is essential for achieving seamless data flow and process automation. Our experienced manufacturing software development team meticulously connects your custom software with other systems to ensure optimal performance. We employ a systematic approach to guarantee a successful integration.

1. Identify Integration Points:

We start by identifying the specific data and process integration points between your custom manufacturing software and existing systems. This involves determining the data to be exchanged, the frequency of data synchronization, and the desired integration outcomes.

2. Define Data Mapping and Transformation:

Next, we establish the data mapping and transformation processes. This includes aligning the data fields and structures between your custom manufacturing software and existing systems, as well as defining any necessary data transformations or conversions to ensure compatibility and consistency.

3. Select Integration Method:

We select the appropriate integration method based on the systems involved and the desired level of integration. This might involve API integration, file-based integration, or database-level integration, tailored to your specific requirements.

4. Develop Integration Components:

Our team creates the necessary integration components, such as APIs, connectors, or middleware, to enable data exchange and process automation. This may involve custom development or leveraging existing integration tools and platforms.

5. Test and Validate Integration:

We conduct a comprehensive evaluation of the integration to ensure data accuracy, system compatibility, and process efficiency. This involves performing end-to-end testing and verifying that the expected outcomes are achieved.

6. Monitor and Maintain Integration:

We continuously monitor the integration to ensure its stability and performance. Regular reviews and updates of the integration components are conducted as needed to adapt to system or business process changes.

Stay ahead in manufacturing! Explore the future with our innovative tools and techniques. Read more about it in our latest article: “Tech Innovations Transforming Manufacturing: Our Advanced Tools and Techniques”.

Integrate with ERP and MES Systems

Integrating custom manufacturing software with Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES) involves mapping data fields, determining integration architecture (such as APIs or middleware), establishing data synchronization processes (real-time or batch processing), automating processes, and implementing error handling mechanisms. This integration fills gaps in processes by enabling seamless information flow across the organization, facilitating ongoing data exchange, and providing real-time visibility into key metrics for informed decision-making. Overall, integrating with ERP and MES systems enhances operational efficiency, reduces errors, and improves organizational performance.

Explore how our custom software solutions enhance manufacturing efficiency. Gain more insightful information through our blog: How Our Custom Software Enhances Manufacturing Efficiency

API- or ESB-based Integrations

API(Application Programming Interface) or ESB (Enterprise Service Bus) based integrations are vital for linking manufacturing software with other corporate software and IoT devices. APIs facilitate communication between different applications, while ESB provides a centralized platform for managing these communications. These integrations enable seamless data exchange, real-time information sharing, and improved operational efficiency. By leveraging API- or ESB-based integrations, manufacturers can automate processes, reduce errors, and enhance productivity. Furthermore, these integrations create a cohesive tech ecosystem, allowing manufacturers to stay competitive by incorporating the latest technologies and innovations.

Integration with Legacy Systems

Integrating custom manufacturing software with legacy systems in manufacturing presents challenges due to outdated technologies, limited interoperability, and lack of documentation. Legacy systems often do not support standard integration protocols like APIs, making seamless integration difficult. However, developing custom software tailored for integration with legacy systems can be a cost-effective and efficient solution. Custom manufacturing software bridges the gap between legacy and modern systems, enabling data exchange and process automation without the need for costly system replacements. Custom manufacturing software can also be customized to meet specific business requirements, ensuring seamless integration that aligns with the organization’s needs. Overall, while integrating with legacy systems poses challenges, custom software development offers a viable solution for achieving seamless integration in manufacturing.

Ready to choose the best SaaS solution partner for your business? Learn more about our expertise and find the perfect fit for your needs through the article.

Endnote

Integrating custom manufacturing software with existing systems is essential for boosting efficiency and staying competitive in the manufacturing industry. A systematic approach ensures a seamless process: identify integration points, define data mapping and transformation, choose the right integration method, develop integration components, test and validate the integration, and establish monitoring and maintenance protocols. Successful integration facilitates real-time data exchange, automates critical processes, and creates a unified technology ecosystem that drives operational excellence.

Contact us today to learn more about how integrating custom manufacturing software can benefit your business. Our team of experts can help you streamline your processes, improve efficiency, and stay competitive in today’s fast-paced manufacturing landscape.