I. Introduction

The manufacturing industry has a rich history of evolution driven by innovation. In today’s highly competitive landscape, Venturesathi understands the crucial need of embracing technology for staying competitive and meeting market demands. The technologies shaping manufacturing innovation are revolutionizing manufacturing processes, enhancing efficiency, and driving growth in the industry.

Venturesathi brings innovation to your manufacturing floor. Explore our software development services tailored for the industry and take the first step towards a tech-driven future.

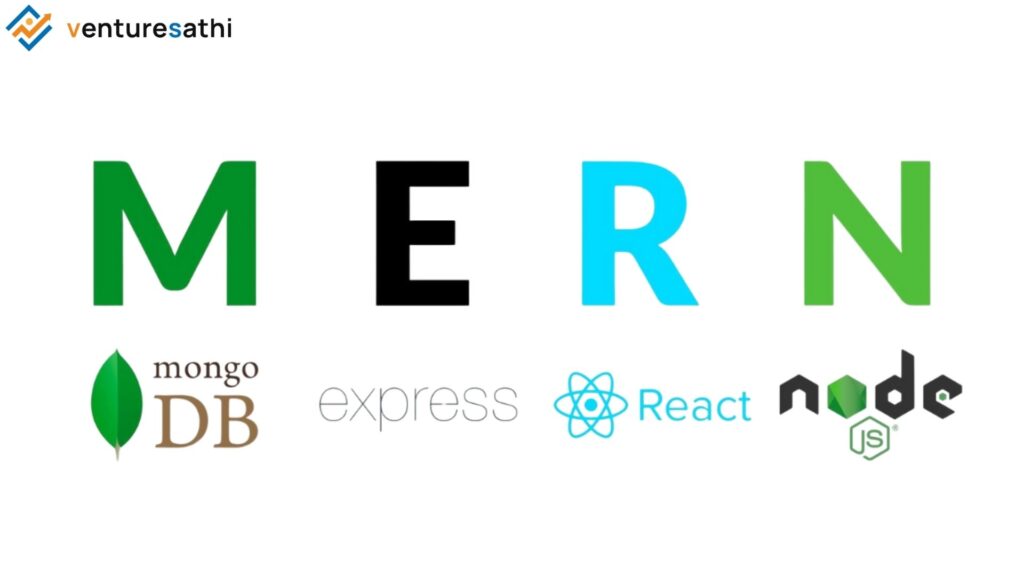

II. Utilizing the MERN Stack in Custom Software Development

At Venturesathi, we leverage the power of the MERN stack – MongoDB, Express.js, React.js, and Node.js – to craft bespoke software solutions tailored specifically to the intricate needs of the manufacturing sector. This modern technology stack serves as a robust toolkit for developing scalable, efficient, and customized web applications that drive productivity and innovation within manufacturing operations.

Advantages of the MERN Stack

The MERN stack offers several advantages that make it an ideal choice for building web applications in the manufacturing sector.

Scalability: MongoDB and Node.js in the MERN stack enable scalable architectures, handling large data volumes and user traffic crucial for manufacturing operations of varying scales and complexities.

Efficiency: The unified JavaScript-based ecosystem of the MERN stack streamlines development, using a single language for both frontend and backend, reducing time and effort while ensuring consistency.

Responsiveness: React.js facilitates highly responsive and interactive user interfaces, vital for manufacturing applications needing real-time data visualization, monitoring, and control.

Ready to revolutionize your production process? Discover how our custom software solutions can enhance manufacturing efficiency and propel your business forward today.

III. Cloud Computing

Cloud computing revolutionizes manufacturing by offering scalable, on-demand access to computing resources and services over the internet.

Cloud-based services facilitate seamless data sharing across different geographic locations, empowering manufacturers to make informed business decisions. Through cloud platforms, stakeholders can access critical information from anywhere, anytime, enhancing collaboration and agility within global manufacturing networks.

Advantages of Cloud Computing

Cost Reduction: By eliminating the need for expensive on-premises infrastructure and maintenance, cloud computing significantly reduces IT costs for manufacturing firms.

Improved Quality Control: Cloud-based analytics enable real-time monitoring of production processes, facilitating proactive quality control measures and minimizing defects.

Shortened Production Times: Cloud computing streamlines collaboration and data sharing among teams, accelerating decision-making processes and reducing time-to-market for products.

Security: Leading cloud providers offer robust security measures, including data encryption, access controls, and regular security updates, ensuring data integrity and confidentiality in manufacturing processes.

Stay ahead of the curve in 2024 with the latest software development best practices! Learn how to implement these strategies to elevate your projects and drive success. Read the full article.

IV. Internet of Things (IoT)

IoT, or the Internet of Things, is a transformative technology that interconnects devices, machines, and systems within manufacturing facilities, enabling real-time data collection, analysis, and communication. This interconnected network forms the foundation of smart manufacturing facilities, where machines and processes are integrated to optimize operations and drive efficiency.

Advantages of IoT

Reduced Downtime: By continuously monitoring equipment and processes, IoT systems can detect issues before they escalate into costly breakdowns, minimizing unplanned downtime and ensuring uninterrupted production.

Improved Quality: IoT-enabled sensors collect data on various parameters, allowing manufacturers to monitor product quality in real-time and implement corrective measures promptly, leading to higher-quality products and customer satisfaction.

Reduced Waste: IoT facilitates predictive maintenance, optimizing equipment performance and extending asset lifespan. This proactive approach reduces waste associated with equipment failures and prevents overproduction, contributing to sustainable manufacturing practices.

Embarking on the journey from concept to code? Dive into our guide on developing a SaaS product and start turning your ideas into reality now!

V. End Note

At Venturesathi, we believe that the future of manufacturing lies in embracing advanced technologies like the MERN Stack, Cloud Computing, and IoT. By investing in innovation and adopting these transformative technologies, manufacturers can position themselves for success in an ever-evolving industry landscape. We are committed to leveraging these tools and techniques to drive growth, efficiency, and sustainability across the manufacturing sector.

Looking to streamline your manufacturing processes and drive efficiency? Partner with Venturesathi for tailored software development services designed to meet your unique needs. Contact us today!